-

- Cut Sheet Laminator This unit is used for pre-made dough sheet in the preparation of hard biscuits especially crackers, (soda or cream) as it overlaps layers of dough sheets which as a consequence give the flaky appearance and texture to the final products. It can also help even the gluten inside the dough sheet.

-

- Three Roller SheetersIt’s used to pre-make dough sheet.

-

- Gauge RollsThrough this gauge roll unit, the prefabricated dough sheets will be made into the required thickness. Rolling speed and transporting speed of each individual gauge roll can be independently controlled, ensuring easy and flexible operation.

-

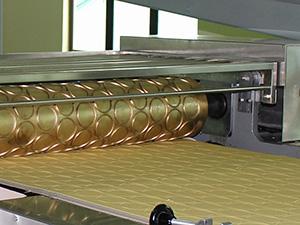

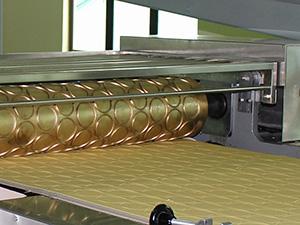

- Rotary Cutter The rotary cutter is an integral part of the rotary cutting group; it receives the dough sheet from the final gauge roll, after the relaxation conveyor, and it has the task of cutting the dough sheet into separate pieces according to desired size and shapes. It consists of two rollers, one for embossing and one for cutting.

-

- Separate Machine

To pick up the scrap and transfer to the lateral scrap return conveyors and then transfer the scrap dough to the hopper of the main forming equipment at the head of the line(e.g. to laminator).

-

- Side Scrap Recycle SystemThe side scrap recycle system is a scrap chute beside the biscuit production lines. After cutting by die roller, the scrap of the dough can be recycled and reused.

-

- Rotary MoulderThis unit is used for the continuous production of soft dough, shortbread, and low fat cookies.

3 driving force (feeding roller, mould, canvas belt).

Adjustabl angle between canvas belt and mould.

-

- Cookie MachineDue to competitive characteristics such as state-of-the-art technology, easy operation, cleaning, and high qualification rate, our Cookie Machine has won great popularity among users around the world, and is the most ideal investment in food processing machinery for investors in the current market.