Egg tart biscuit machine

- Maximum capacity: 450—500PCS /min

- Mainly used for filling the surface of cookies (or biscuits)

- Sprinkle with almond grains (or peanuts, sesame seeds, etc.)

- Chocolate cookie cooling

- The egg tart biscuit machine has triple motivity.

- This machine is equipped with frequency converter, PLC and touch screen.

- The electrical control system is from Schneider, France.

- The roller side is made of Nylon.

- It has stainless steel cover.

- The belt conveyor is annular and made of canvas.

Features:

The egg tart biscuit machine can be suitable for demold of dough of different kinds such as dough for big biscuits, hard dough and soft and sticky dough.

S type paddle, mixing 375kg flour per time (650kg dough)

650 Horizontal mixer is suitable for hard dough (hard biscuit production) and soft dough (soft biscuit production).

- All functions can be controlled by touch screen.

- Multi-speed mixing can fulfill optimal mixing requirement.

- Jacket water circulation heating provide suitable mixing temperature under different circumstance.

- Inverter+PLC soft start reduce Energy consumption and extend service life.

Salt/Sugar Sprinkler (full stainless steel)

To sprinkle sugar or salt on the dough pieces before baking, using rotary brush roller.

- Sprinkle salt/ sugar evenly.

- Independent design, easy to move, clean and maintain.

- By adopting mesh belt type instead of PU belt, it does better in ingredient recycle avoid ingredient squander, easy cleaning.

- Adopt 316stainless steel hopper, 304stainless steel Bearing, screw, nut, roller, axle, adjusting base and driving wheel to ensure clean and sanitary, no rust.

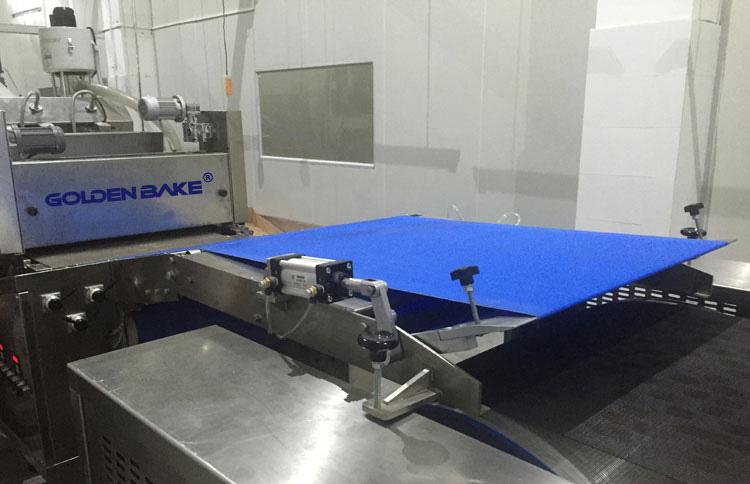

Entrance Transfer Machine

- In trial running stage or oven pre-heat stage, while oven running and no dough pieces come, pneumatically lift rear part to avoid heating from oven mesh belt so as to extend PU belt working life.

- In trial running stage, pneumatic retract front part for easily retrieve dough pieces, avoid squander while them go into oven.

- PU belt adopt pneumatic tension and loose, can be release in loose status in day end.

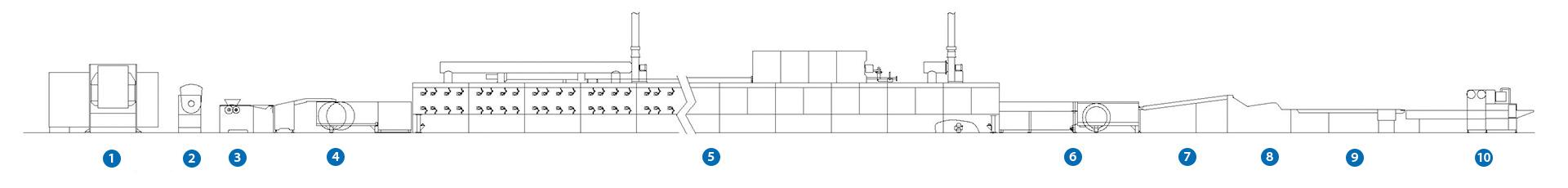

Hybrid Gas Oven

4 functional temperature zones

Dough leavening-dough shaping-dough dehydration-coloring

The first and second temperature zones: direct fired temperature zone

The third and forth temperature zone: hot air convection

- The hybrid gas oven can be controlled by human-computer interface.

- The ignitron can be selected manually so that the flame size can be adjusted according to products.

- It adopts DC motor as the power unit during power outages.

- The mesh belt adopts pneumatic deviation rectifier.

Adjustable Hot Wind Convection Baking Oven (Electrical)

- 4 temperature zones

- PID+PLC temperature control system

- The air exhausters for each temperature zone can realize variable speed adjustment.

- It adopts DC motor as the power unit during power outages.

- The mesh belt adopts pneumatic deviation rectifier.

Straight Line Type Cooling Conveyor

Clip-Type Cooling Conveyor

Overhead Type Cooling Conveyor

Z-Type Cooling Conveyor

Rotary Stacker

Penny stacker

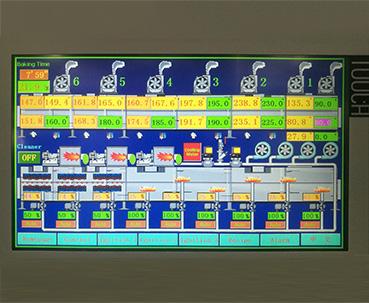

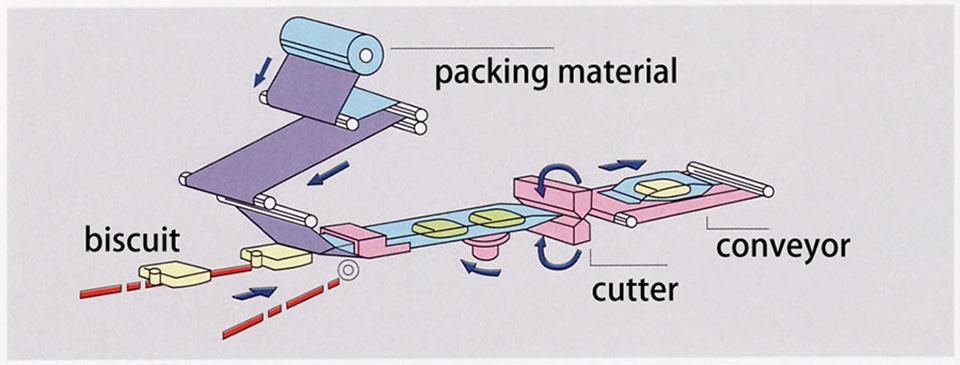

Horizontal packing machine

The human-machine interface (HMI) can realize programmable logic control (PLC). The information can be displayed on the screen intensively. The workers can operate the machine via the touch screen and they have the access to biscuit formula at any time. The formula proportion of each kind of biscuit is different from each other, so the processing parameters of the machine are different as well. After making one kind of biscuit, the data can be recorded. You can choose the data directly without machine adjusting when making this biscuit again. The production line consists of many single machines, the data of all the machine units can be showed on one screen intensively with PLC control. By setting of the parameters, the machine can be easily controlled.

These are the main brands of the units used for the whole production line, including the system accessories of PLC and HMI. These are all international brands.

Golden Bake

Head office:

NO.1, FuTian Road, Nan Xi Industrial Zone Xiang Zhou, Zhuhai, China 519075

Factory:

Smart-Tech Machinery Manufacturing Co.,Ltd

Add: Area A, 1st Floor, Building A, No. 4, Jialian Road, Tanzhou Town, Zhongshan, Guangdong, China

Huapu Food Machinery Manufacturing Co.,Ltd:

Add: NO.13pinggong 1 road, Nanping Science&Technology Industrial Zone, Zhuhai, Guangdong, China

Zhongshan Tianxiang Food Machinery Co.,Ltd:

Add: B2, Yuzhou Industrial Zone, No. 2, 5th Street, Yukang Road, Tanzhou Town, Zhongshan City