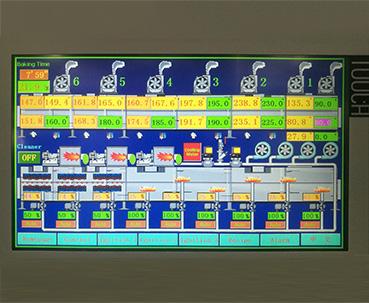

PLC and HMI

The human-machine interface (HMI) can realize programmable logic control (PLC). The information can be displayed on the screen intensively. The workers can operate the machine via the touch screen and they have the access to biscuit formula at any time. The formula proportion of each kind of biscuit is different from each other, so the processing parameters of the machine are different as well. After making one kind of biscuit, the data can be recorded. You can choose the data directly without machine adjusting when making this biscuit again. The production line consists of many single machines, the data of all the machine units can be showed on one screen intensively with PLC control. By setting of the parameters, the machine can be easily controlled.

These are the main brands of the units used for the whole production line, including the system accessories of PLC and HMI. These are all international brands.